Chemical-physical processes

Chemical-physical wastewater treatment plants

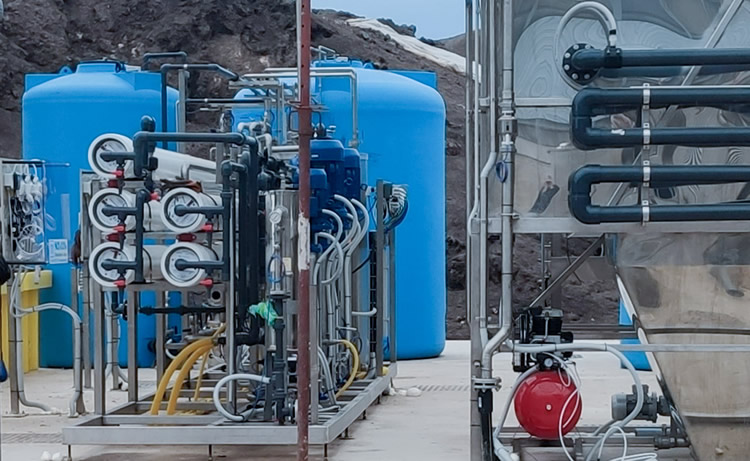

Chemical-physical treatment plants include all those systems that remove the pollutants in the wastewater, usually the elements that are not easily biodegradable, using chemical additives called reagents. These substances react with the pollutants making them insoluble and facilitating their removal.

Flotation process

Flotation is a water clarification treatment that removes suspended solids such as oils, grease, fibres and other low-density materials. The treatment dissolves air in the water under pressure. As the air bubbles rise, they drag the suspended particles with them, which remain on the surface as foam. This foam is then removed from the surface of the water with the help of a skimming device. To achieve the best possible result, the wastewater to be treated is dosed with a coagulant (mineral salts), such as ferric chloride or aluminium polychloride and a flocculant (polyelectrolyte) and soda for pH correction. The floater is customised with the electrical panel and PLC to control the process.

Alkaline degreasing process

Alkaline degreaser baths are used to remove oil and grease from the metal surfaces. The alkaline degreasing process consists of purification of the metal preparation baths before galvanic treatments or oil emulsions. Its objective is reuse in the production cycle. We supply specific plants for the industrial sector.

AOP

Advanced Oxidation Processes

Advanced oxidation processes to treat wastewater are characterised by the formation of hydroxyl radicals in water, which are highly oxidising. AOP is mainly used to treat wastewater with high biorefractory organic loads for which it is necessary to improve the BOD5/COD. Examples include landfill leachates, digestates and vegetation water.

Request info

Contact us for information on water treatment and for more details about our services

Request a site visit

Request a free site visit for an initial consultation on wastewater treatment